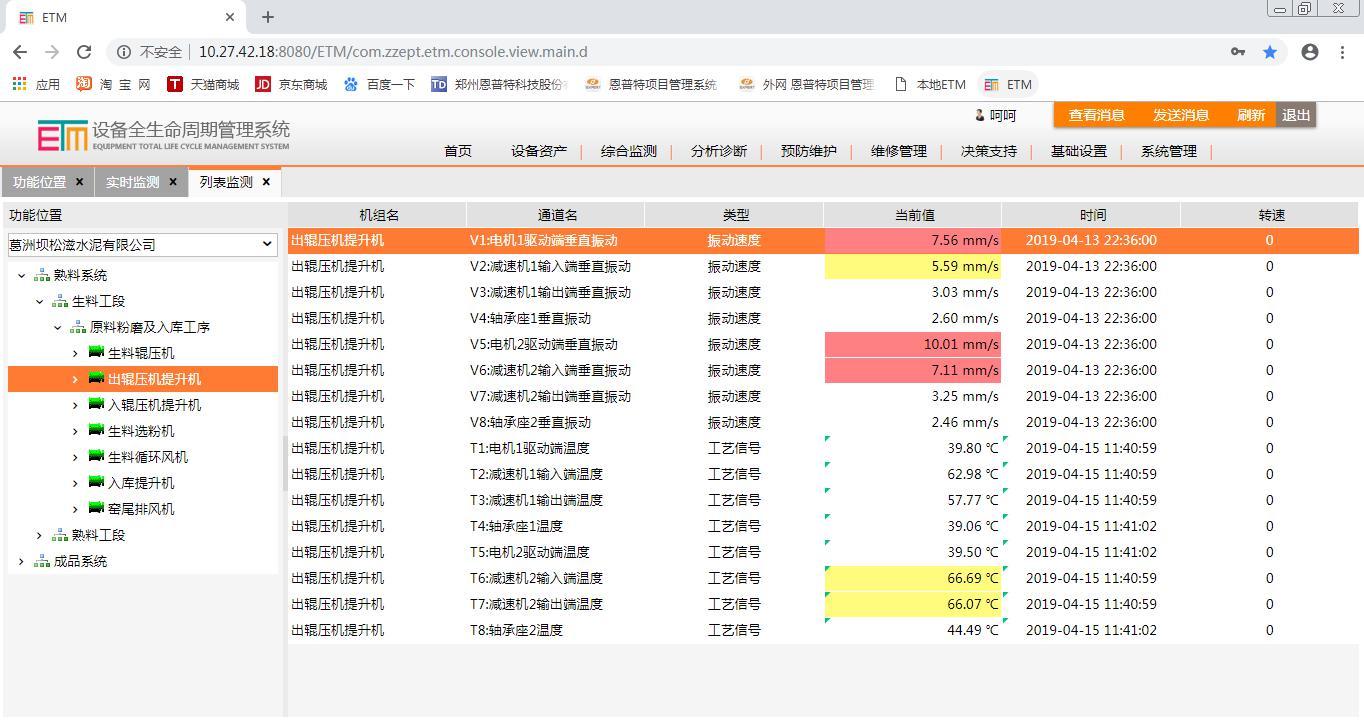

葛洲坝松滋水泥有限公司智能巡检系统项目

Time:

2020-04-27

The intelligent patrol inspection system is applied to the raw material and clinker system of No.2 production line of Gezhou dam Songzi cement co., LTD., which involves the installation of temperature and vibration sensors on the bearing seat of the main engine and key equipment to realize real-time monitoring. To establish a point inspection task for routine or prone to failure of auxiliary equipment, and paste the RF card in the field for the inspector punching out inspection; Online monitoring data, point inspection data and key data of DCS system are obtained and monitored by the intelligent inspection system through information means. A system with full coverage, large-scale distributed data collection, centralized management and comprehensive utilization shall be built to form a new mode of monitoring, diagnosis and information-based management of equipment point inspection condition. Establish a set of comprehensive enterprise equipment life cycle management system to meet customer requirements. This project involves online monitoring of 25 key equipment, and a total of 181 vibration and temperature measuring points are installed, and 27 data collectors are deployed on site. In addition, the intelligent patrol inspection system covers the main equipment in the factory.

Previous:

Next:

Previous:

Next: